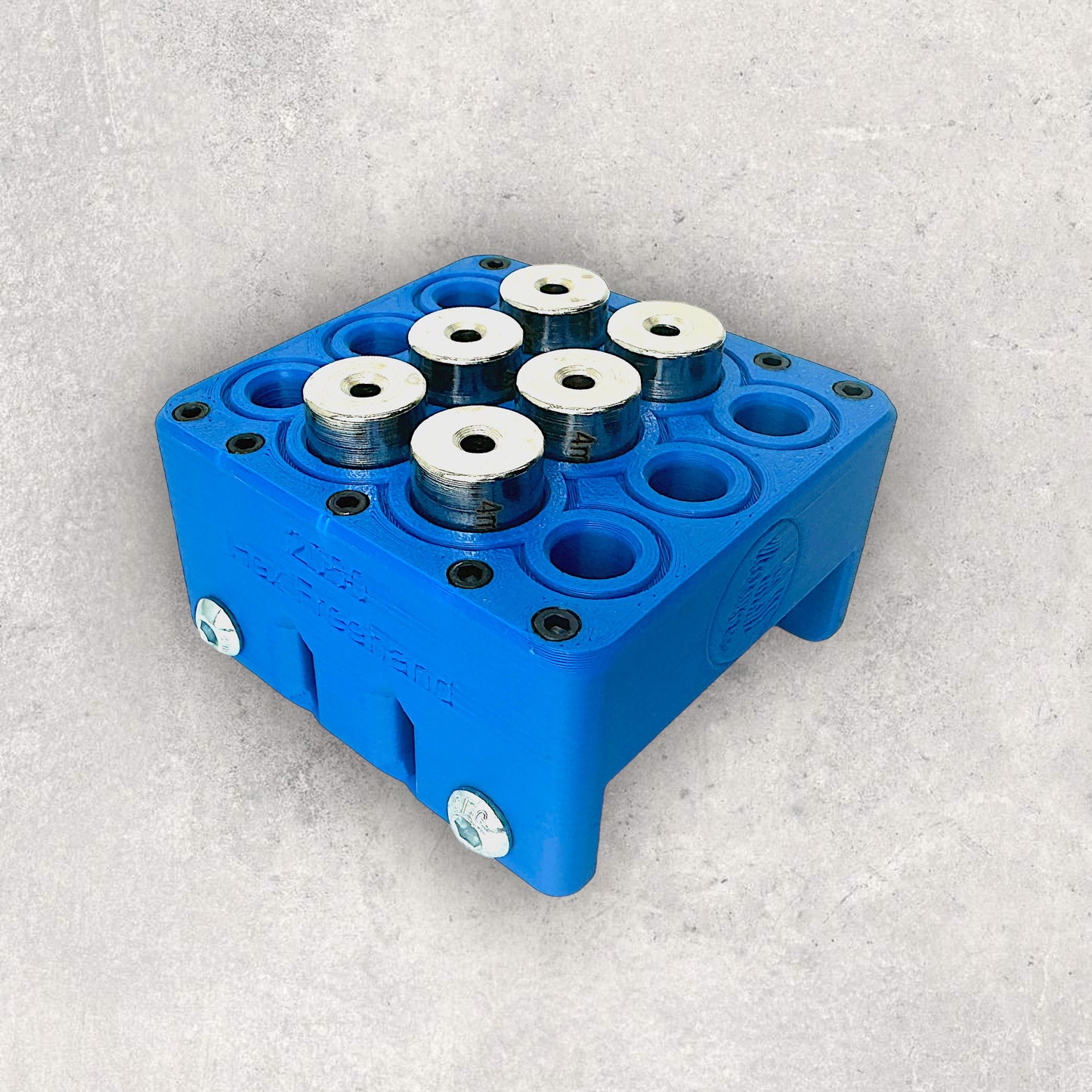

2060 Hex Freehand Drilling Jig V2

2060 Hex Freehand Drilling Jig V2

Couldn't load pickup availability

Aluminum Extrusion Precision Drilling Jig

This Drilling Jig enables you to precisely drill 6 holes, 20mm apart, at any location of the extrusion, facilitating a 'Blind Joint.' Such joints reduce the reliance on external brackets, resulting in more aesthetically pleasing joinery without compromising on strength.

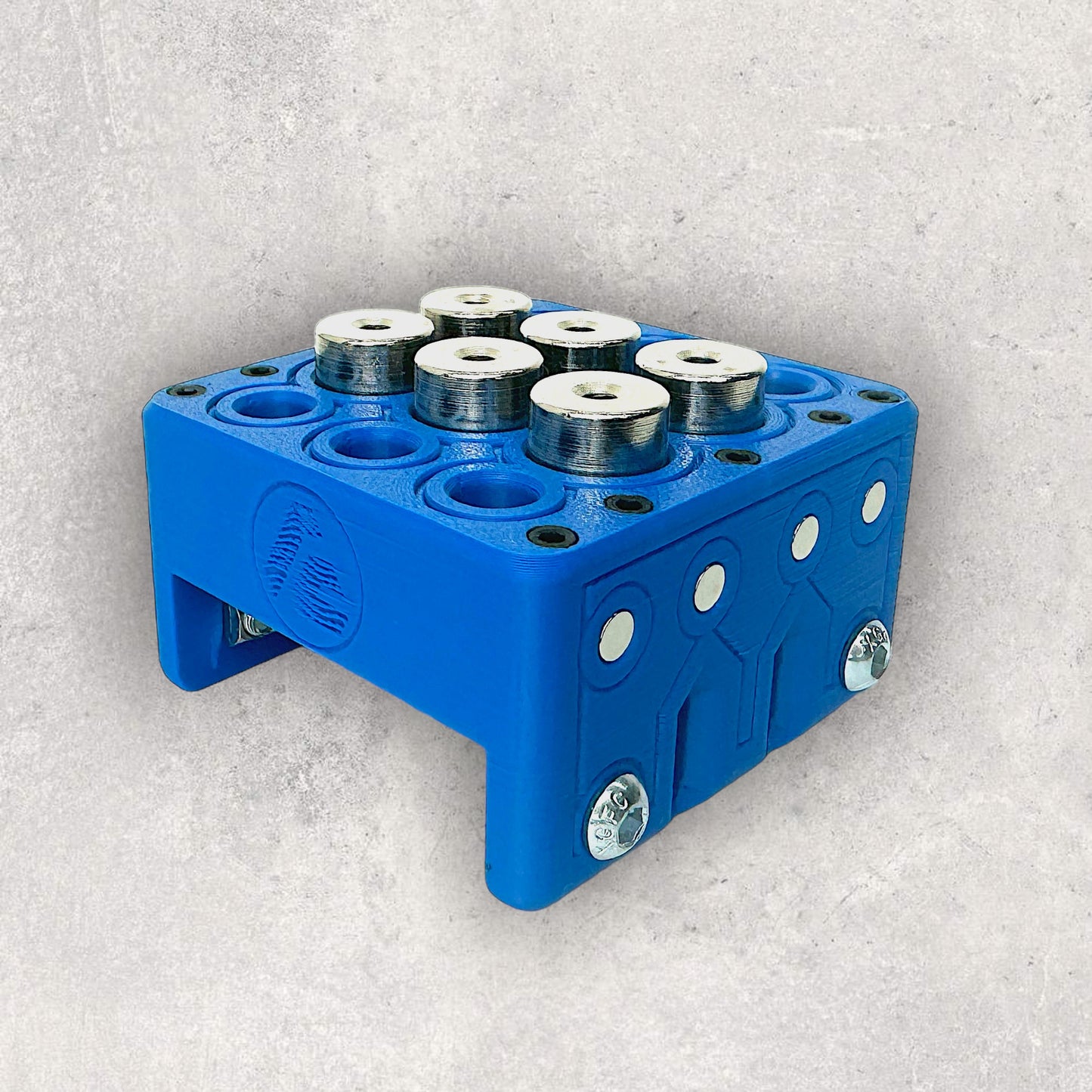

These are high-quality 3D-printed precision 8020 aluminum extrusion drilling jigs designed and produced by 'The Aluminum Carpenter' to work with all 20 Series Aluminum Extrusions. Additionally, all necessary bolts and nuts are included, allowing for immediate use straight out of the box. Equipped with two magnets, this attachment easily adheres to any magnetic surface, providing an organized storage solution.

These jigs are meticulously designed and 3D modeled, with all fitting and hole tolerances keenly monitored. They are slowly and carefully printed one layer at a time, with each jig print taking over five hours, depending on the size of the jig.

With this precision drilling jig, you can quickly, consistently, and repeatedly achieve accurate hole placements without the need for additional tools, saving you tremendous time and gaining immediate accuracy in your work.

How To Use Our Precision Jigs

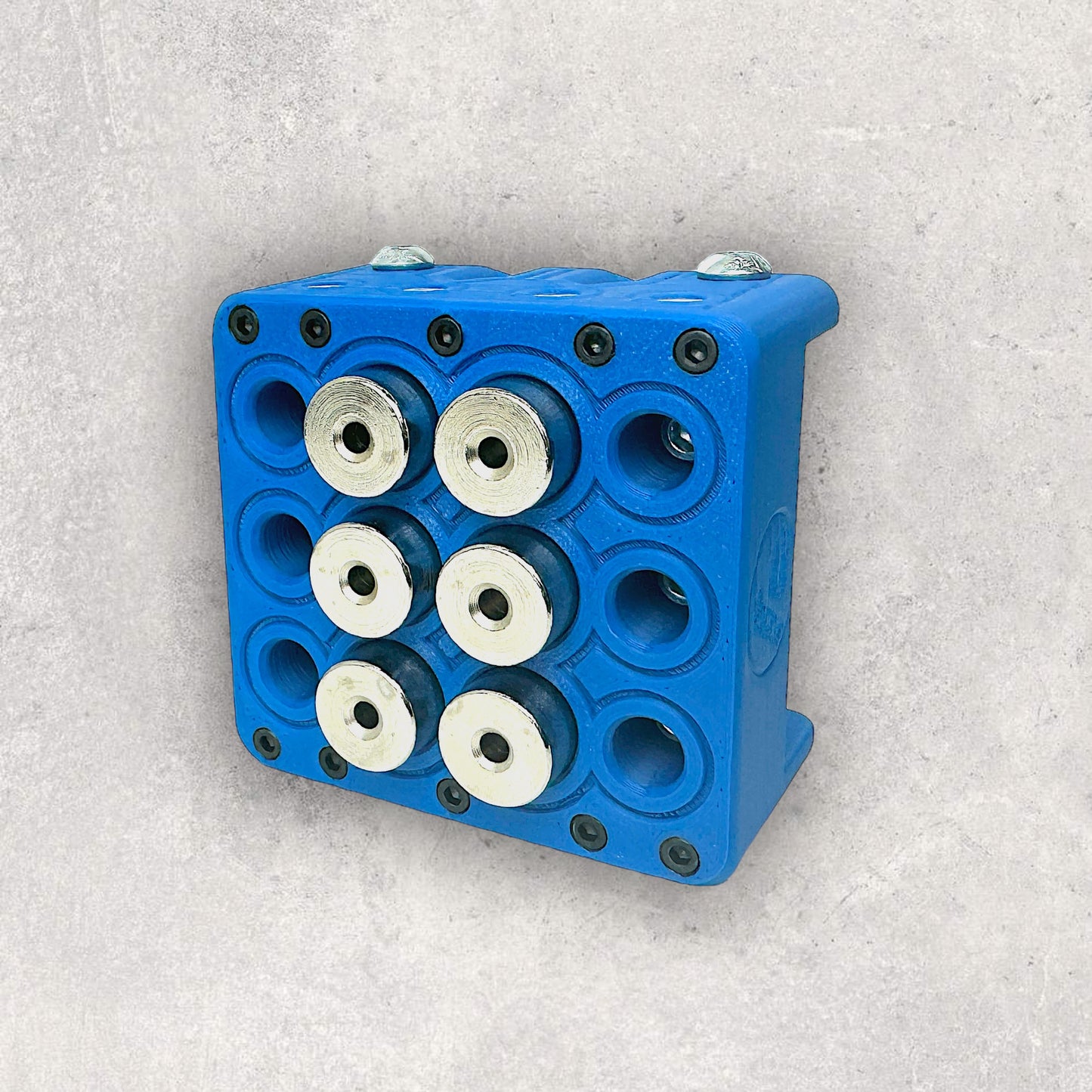

There are many ways to secure the jig to your aluminum extrusion. In most instances, you do not need to utilize every single bolt and nut. Simply determine the best way to securely fasten the jig to your workpiece. The multiple bolts provide numerous fastening options to cater to a variety of scenarios.

Once the jig is securely fastened to your workpiece, you can immediately drill extremely precise holes into your aluminum extrusion. This enables a wide range of joinery methods that would be impossible without drilling.

For Offset Jigs, you do not need to measure or draw any marked lines on your workpiece.

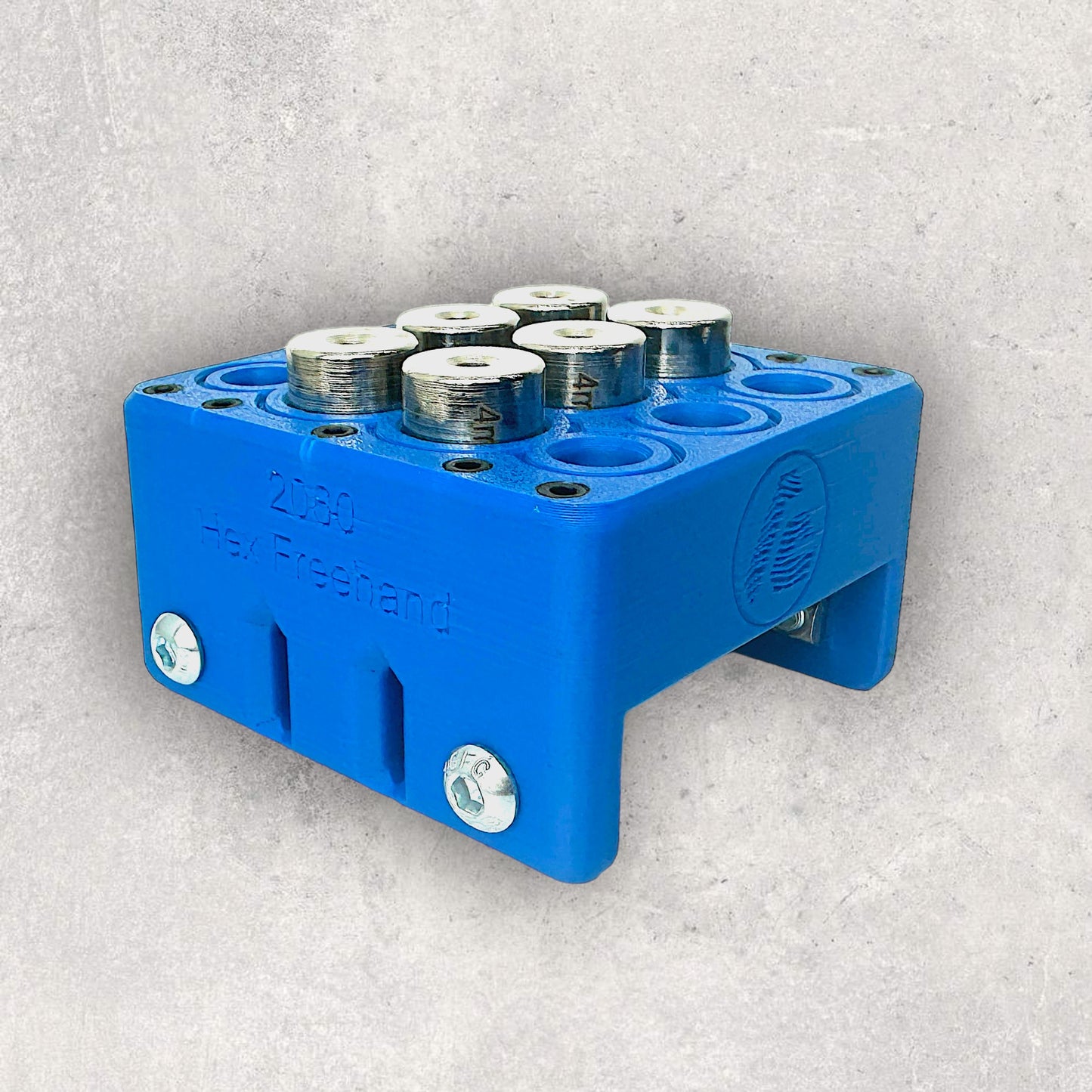

For Freehand Jigs, measure and mark your aluminum extrusion where you want to place a drilled hole. Align the gap on the sides of the jig with your marked line. The exact center of the gap is precisely aligned with the center of the drilled hole.

Improved Version 2 Precision Jigs

Our Version 2 jigs are significantly improved from Version 1.

- Thicker 3D-printed walls, reinforced with bolts.

- Improved aesthetics with rounded edges and geometrical facial layouts.

- Refined and optimized print settings for enhanced strength and weight reduction.

- Drill guide bushings are secured with heat-resistant, high-strength threadlocker.

- Complete set of bolts and nuts provided for all possible securing methods.

Share